What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

In recent years, the 3D CNC machine industry has witnessed unprecedented growth, driving innovations in manufacturing and design across various sectors. According to a report by MarketsandMarkets, the global 3D CNC machine market is projected to reach USD 5.2 billion by 2025, growing at a compound annual growth rate (CAGR) of 15.2% from 2020 to 2025. This surge in demand is attributed to the increasing adoption of additive manufacturing technologies, which enable enhanced precision and efficiency in production processes.

Industry experts, such as Dr. Lisa Thompson, a leading authority in CNC technology, emphasize the transformative potential of 3D CNC machines. As she aptly states, "The shift towards 3D CNC machines marks a pivotal moment in manufacturing, merging automation with sophisticated design capabilities." This evolution not only optimizes production workflows but also opens new avenues for innovation in industries ranging from aerospace to healthcare. As we explore the features and benefits of 3D CNC machines, it becomes evident that their impact will reshape future industrial practices and drive significant economic growth.

Understanding the Basics: What is a 3D CNC Machine?

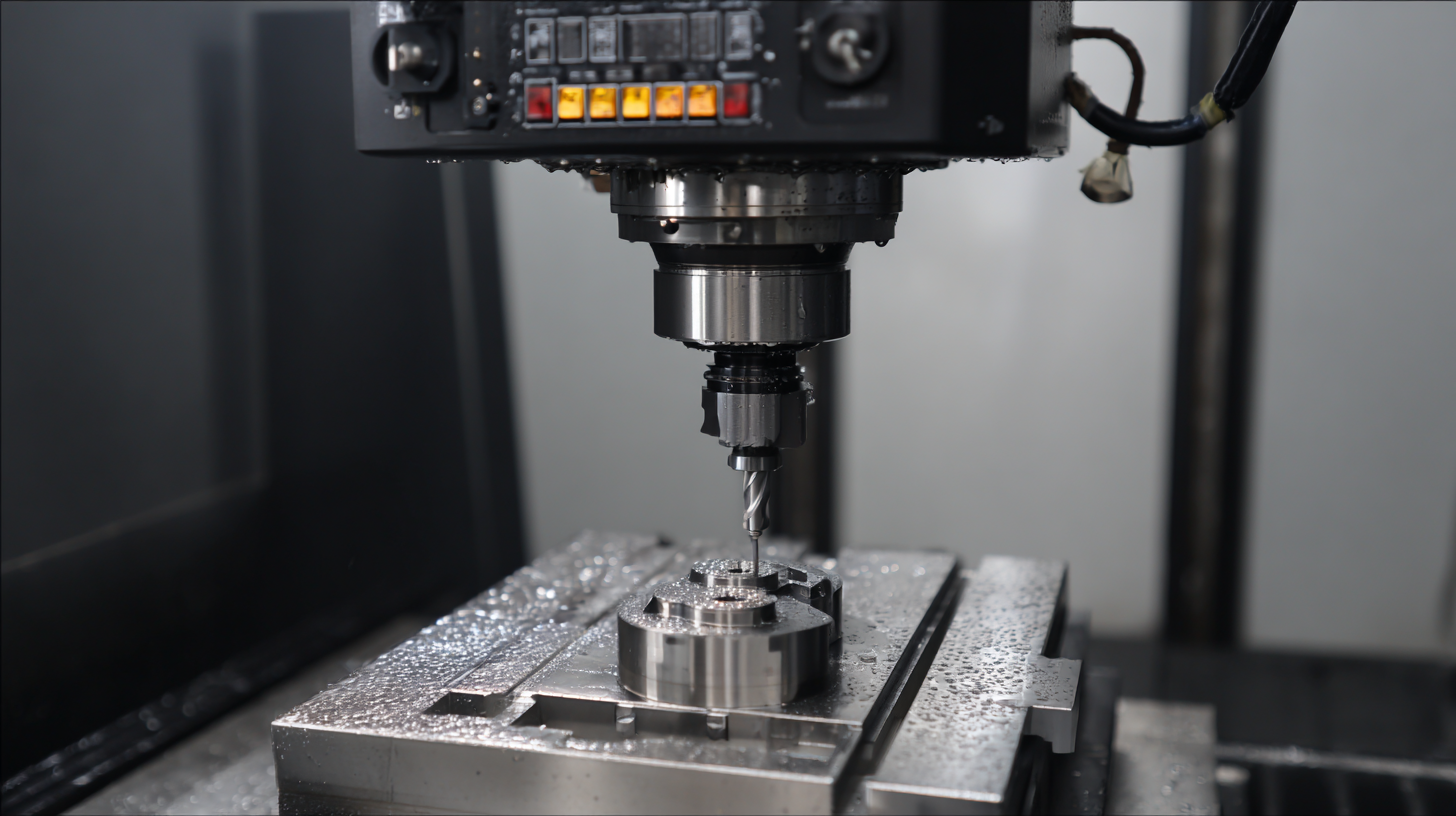

A 3D CNC (Computer Numerical Control) machine is a sophisticated tool that automates the process of cutting, milling, and shaping materials to create three-dimensional objects. These machines utilize computer programs to direct various types of tooling, allowing for remarkable precision and repeatability in production. The core principle behind a 3D CNC machine involves translating digital designs into physical forms through a series of controlled movements along the X, Y, and Z axes. This capability opens up a world of possibilities in various industries, including manufacturing, aerospace, automotive, and even art.

One of the standout features of a 3D CNC machine is its versatility. It can work with a wide range of materials, such as plastics, metals, and wood, enabling it to cater to diverse applications. The benefits of using a 3D CNC machine are manifold: increased efficiency, reduced waste, and the ability to produce complex shapes that would be challenging to achieve with traditional manufacturing methods. As industries continue to grow and evolve, the demand for 3D CNC machines is projected to rise significantly, driven by advancements in technology and a push for higher productivity and customization in manufacturing processes.

Key Features That Set 3D CNC Machines Apart from Traditional Machines

3D CNC machines have gained significant traction in various industries due to their advanced technology and unmatched precision. Unlike traditional CNC machines that largely focus on subtractive manufacturing, 3D CNC machines utilize additive processes to create complex structures layer by layer. This capability allows for the production of intricate geometries that would be challenging, if not impossible, to achieve with conventional machining. A report by MarketsandMarkets projects that the 3D printing market, which includes 3D CNC technology, is expected to grow from $9.3 billion in 2020 to $35.4 billion by 2026, highlighting the increasing demand for additive manufacturing solutions.

3D CNC machines have gained significant traction in various industries due to their advanced technology and unmatched precision. Unlike traditional CNC machines that largely focus on subtractive manufacturing, 3D CNC machines utilize additive processes to create complex structures layer by layer. This capability allows for the production of intricate geometries that would be challenging, if not impossible, to achieve with conventional machining. A report by MarketsandMarkets projects that the 3D printing market, which includes 3D CNC technology, is expected to grow from $9.3 billion in 2020 to $35.4 billion by 2026, highlighting the increasing demand for additive manufacturing solutions.

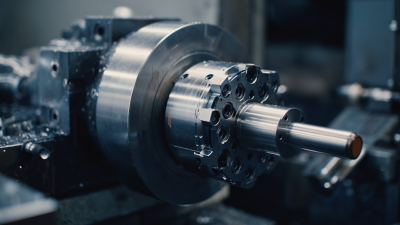

The key features that distinguish 3D CNC machines are their versatility and material compatibility. While traditional machines typically work with metals and plastics, 3D CNC machines can handle a wider range of materials, including ceramics and composites. This flexibility allows manufacturers to innovate and rapidly prototype products across various sectors, such as automotive and aerospace. Additionally, the automated nature of 3D CNC machining leads to reduced production times and lower labor costs, with studies indicating that companies can achieve up to 70% cost reductions in prototyping by employing additive techniques. The ability to efficiently produce customized parts on demand represents a transformative shift in manufacturing processes, shaping the future of industry standards.

Advantages of Using 3D CNC Machines in Modern Manufacturing Processes

3D CNC machines have revolutionized modern manufacturing processes by providing unmatched precision and efficiency. One of the primary advantages of using these machines is their ability to produce complex geometries with minimal human intervention. This capability not only reduces the chances of errors but also significantly shortens production times. As a result, manufacturers can respond swiftly to market demands and customize products to suit specific customer needs without sacrificing quality.

Another significant benefit is the cost-effectiveness of 3D CNC machines. By automating key stages of production, companies can lower labor costs while also minimizing material waste through advanced design and cutting techniques. Furthermore, the scalability of 3D CNC technology allows businesses to ramp up production easily, catering to both small batches and large-scale manufacturing projects with equal efficiency. The integration of such technology positions companies favorably in a competitive market, leading to enhanced productivity and profitability.

What is a 3D CNC Machine? Exploring Features, Benefits, and Industry Growth Projections

| Feature | Description |

|---|---|

| Precision | 3D CNC machines offer high precision with tolerances up to ±0.001 inches. |

| Material Versatility | Can work with a variety of materials including metals, plastics, and composites. |

| Automation | Automated processes reduce human error and increase consistency in production. |

| Production Speed | Faster production times compared to traditional machining methods. |

| Cost-Effectiveness | Reduces waste and lowers production costs over time due to efficiency. |

| Industry Growth Projection | Expected growth rate of 25% annually in the 3D CNC machinery market through 2027. |

Market Trends and Growth Projections for the 3D CNC Machine Industry

The 3D CNC machine industry is witnessing significant growth, characterized by promising market trends and projections. With the global machining center market valued at $29.17 billion in 2018, it is expected to exhibit a compound annual growth rate (CAGR) of 4.9%, reaching new heights by 2032. In parallel, the CNC machine tool market is projected to exceed $85.89 billion by 2025, fueled by developments in the construction industry and advancements in additive manufacturing technologies, particularly 3D printing.

Moreover, specialized sectors such as jewelry making and precious metal processing equipment are also on an upward trajectory. The market size for this segment is anticipated to grow from $1.5 billion in 2024 to approximately $2.74 billion by 2034, reflecting a CAGR of 6.3%. The metalworking industry, including CNC machining services, will continue to leverage new technologies to enhance production efficiency and meet evolving consumer demands, indicating a robust future for 3D CNC machines across various sectors.

Applications of 3D CNC Machines in Various Sectors and Their Impact

3D CNC machines have revolutionized various industries by providing precision and efficiency in the manufacturing process. These machines are instrumental in sectors such as aerospace, automotive, medical, and consumer goods. In aerospace, for instance, 3D CNC machining allows for the production of complex components that enhance aircraft performance while minimizing weight. Similarly, in the automotive industry, these machines facilitate rapid prototyping, enabling manufacturers to test designs quickly and reduce time to market.

Moreover, the medical field benefits significantly from 3D CNC technology, especially in creating custom implants and prosthetics tailored to individual patients’ specifications. This personalization not only improves patient outcomes but also increases the demand for precision-engineered medical devices. Additionally, in consumer goods, 3D CNC machines enable mass customization, allowing brands to cater to unique customer preferences while maintaining cost-effectiveness. As industries continue to adopt this technology, its impact on efficiency, sustainability, and innovation is poised to grow, reshaping the future of manufacturing.

Related Posts

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking the Secrets of CNC Programming for Beginners in Modern Manufacturing

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes

-

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques