Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency

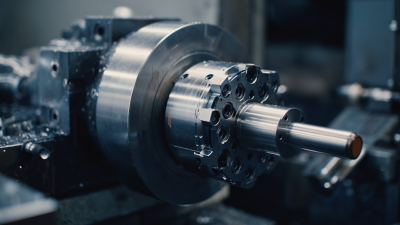

In the ever-evolving landscape of precision manufacturing, the advent of advanced CNC controllers is heralding a new era marked by a remarkable 30% increase in operational efficiency. As industry experts highlight, these sophisticated systems enable manufacturers to elevate their production capabilities, reduce wastage, and improve the overall quality of their products. Renowned CNC technology expert, Dr. Henry Adams, aptly stated, “The integration of state-of-the-art CNC controllers transforms conventional manufacturing into a streamlined process, allowing for unprecedented levels of accuracy and productivity.”

The significance of CNC controllers cannot be overstated; they serve as the backbone of modern automated machining processes. By harnessing the power of digital technology, these controllers provide manufacturers with the tools to program and control machines with pinpoint precision. This revolutionary shift not only enhances the manufacturing process but also positions companies to remain competitive in a rapidly changing market. As businesses strive for excellence, the implementation of high-efficiency CNC controllers stands out as a vital strategy for success in the manufacturing realm.

The Evolution of CNC Controllers in Precision Manufacturing

The evolution of CNC controllers has markedly transformed the landscape of precision manufacturing, with recent advancements pushing efficiency to unprecedented levels. According to market analyses, the global CNC machines market is surging, anticipating a growth trajectory that will witness it reaching USD 2.8 billion by 2035, with a compound annual growth rate (CAGR) of 5.3% from 2025. This remarkable growth underscores the critical role of digital manufacturing technologies in enhancing productivity across a diverse range of industries.

Leading the charge in this evolution are pioneering innovations such as SINUMERIK ONE, which epitomizes the pinnacle of digital control technology. This cutting-edge system enables manufacturing processes that are not only faster but also yield greater precision, meeting the demands of an ever-evolving market. Additionally, the introduction of AI-powered CNC routers, like those from Tommotek, illustrates how integrating smart technologies into traditional CNC machining can drive both efficiency and sustainability, exemplifying a new era where precision manufacturing is intertwined with technological advancement.

Understanding CNC Controllers: Revolutionizing Precision Manufacturing with 30% Higher Efficiency

| Parameter | Traditional CNC Controller | Modern CNC Controller | Efficiency Improvement (%) |

|---|---|---|---|

| Programming Ease | Moderate | High (Visual Programming) | - |

| Processing Speed | 100 ipm | 130 ipm | 30% |

| Feedback Loop Frequency | 1 kHz | 10 kHz | - |

| Precision Range | ±0.005 mm | ±0.001 mm | - |

| User Interface | Basic | Interactive Touchscreen | - |

| Energy Consumption | 1500 W | 1200 W | 20% |

Key Features that Enhance CNC Efficiency by 30%

The CNC (Computer Numerical Control) machinery market is expected to see significant growth, with projections indicating a worth of approximately $95.6 billion by 2025, expanding to about $141.3 billion by 2033. This growth underscores the increasing demand for precision manufacturing solutions, driven by manufacturers seeking to enhance productivity and efficiency. As industries embrace digital manufacturing technologies, the adoption of advanced CNC controllers can lead to operational improvements, including a reported 30% increase in efficiency.

Key features of modern CNC controllers play a crucial role in achieving these efficiency gains. Innovations such as adaptive feed-rate control, real-time monitoring, and intuitive user interfaces are designed to optimize machining processes. By transitioning from conventional operations to automated solutions, manufacturers can not only reduce production time but also lower operational costs. The shift towards environmentally friendly machines further emphasizes the need for high-precision tasks, catering to a market increasingly focused on sustainability while meeting rigorous manufacturing standards. As companies continue to integrate these advanced controllers, the landscape of precision manufacturing will undoubtedly be revolutionized.

Comparative Analysis of Top CNC Controller Brands

The CNC controllers landscape is witnessing a significant evolution, marked by a comparative analysis of leading brands that promise enhanced efficiency for the precision manufacturing sector. As industries increasingly rely on automation and sophisticated technology, the need for CNC controllers that offer improved performance and reliability has never been greater. A focus on top brands reveals a commitment to innovation, with advancements aimed at achieving up to 30% higher efficiency in operations, setting new standards for production output and quality.

Furthermore, the global CNC machine market is projected to experience substantial growth over the next decade. This expansion is indicative of a broader shift in manufacturing practices across various sectors, including woodworking and metal fabrication. The CNC market, with its anticipated growth from $101.22 billion in 2025 to $195.59 billion by 2032, showcases an impressive CAGR of 9.9%. As competition intensifies, brands are positioning themselves not only through technological advancements in CNC controllers but also by addressing the evolving demands of manufacturers globally. This competitive landscape is pivotal for maintaining a strong foothold in the rapidly advancing industrial sector, particularly as emerging markets like China continue to innovate and challenge traditional manufacturing powerhouses.

Real-World Applications: Success Stories in Precision Manufacturing

The integration of CNC controllers in precision manufacturing has led to a remarkable transformation, resonating through various sectors. Take, for instance, the aerospace industry, where the meticulous demands for reliability have catalyzed the rise of precision manufacturing techniques. Companies have leveraged advanced CNC technology to achieve higher efficiency and accuracy in production processes. One success story involves a prominent aerospace manufacturer that significantly enhanced productivity by implementing state-of-the-art CNC controllers, resulting in a 30% increase in operational efficiency while ensuring compliance with stringent regulatory standards.

Similarly, the automotive sector has witnessed notable advancements. By utilizing CNC technology, manufacturers have streamlined their production lines, drastically reducing downtime and enhancing product quality. A leading automotive producer, for instance, reported substantial cost savings and reduced lead times after adopting CNC systems, emphasizing the adaptability and transformative potential of these tools. Real-world applications showcase how precision manufacturing, driven by CNC controllers, is not only redefining production efficiency but also solving complex manufacturing challenges across various industries.

Future Trends in CNC Technology and Their Impact on Manufacturing

The landscape of CNC technology is evolving rapidly, driven by advancements in machine tools and the integration of artificial intelligence. The global CNC machine tools market is projected to grow by USD 21.9 billion from 2025 to 2029, fueled by demand for high-precision and multi-axis machining centers. This growth is indicative of the industry's shift towards increased efficiency and productivity, enabling manufacturers to achieve up to 30% higher efficiency with new CNC controllers.

As these technologies develop, we anticipate significant trends shaping the future of CNC machining. The rise of five-axis capabilities is particularly noteworthy, allowing for more complex geometries and reduced setup times. Companies like Rapid CNC Services are already capitalizing on this trend, positioning themselves strategically to meet the evolving demands of precision manufacturing.

Tip: To stay competitive, manufacturers should invest in training their workforce on the latest CNC technologies and software. Emphasizing continuous education will ensure that teams are prepared to leverage advancements effectively.

Additionally, automation and AI are redefining operational efficiencies, especially in the context of additive manufacturing and CNC metal cutting. Understanding these trends will be crucial for businesses aiming to enhance their production processes and adapt to future market needs.

Tip: Regularly reviewing market insights and reports can provide valuable foresight into future trends and help businesses optimize their investment strategies in CNC technology.

Related Posts

-

Exploring the Future of Manufacturing with CNC Machining Centers and Their Innovative Applications

-

Unlocking the Future of Manufacturing with Precision CNC Machining Techniques

-

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

-

Unlocking Precision: How CNC Solutions Revolutionize Modern Manufacturing Processes