Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

In the ever-evolving landscape of modern manufacturing, the advent of VMC machines has heralded a new era of precision and efficiency. These Vertical Machining Centers, or VMC machines, have revolutionized traditional manufacturing techniques by integrating advanced technology with automation. By harnessing the power of computer numerical control (CNC), VMC machines allow for unprecedented accuracy in the production of complex parts and components across various industries. This article delves into the transformative capabilities of VMC machines, exploring how they optimize processes, reduce waste, and enhance productivity. From intricate designs to high-volume production, the versatility of VMC machines presents invaluable insights and practical tips for manufacturers aiming to stay competitive in a rapidly changing market. Join us as we unlock the precision that defines the future of manufacturing.

Understanding VMC Machines: A Beginner’s Guide to Vertical Machining Centers

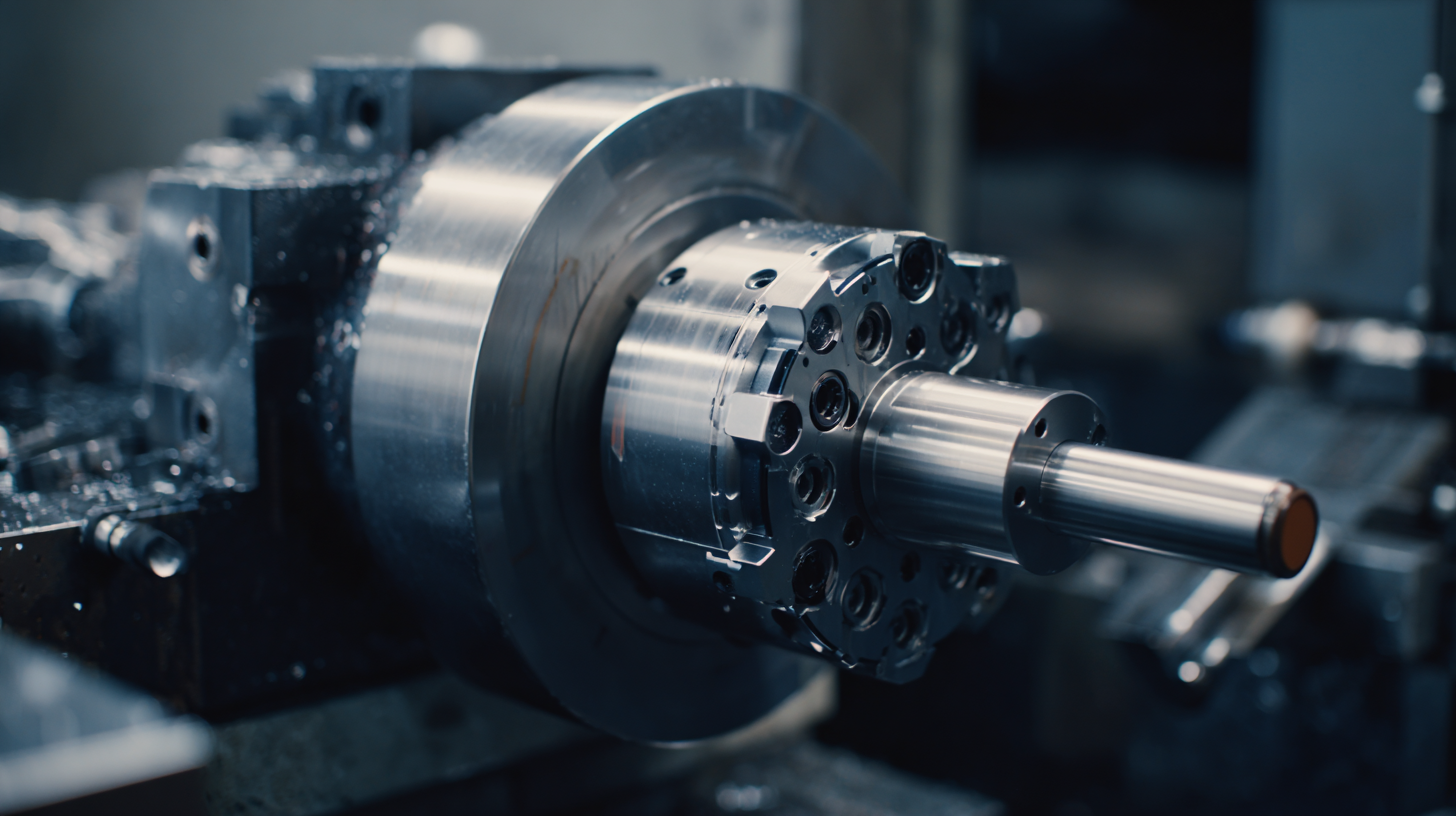

Vertical Machining Centers (VMC) have become essential in modern manufacturing, offering precision and efficiency for a wide range of machining applications. A VMC primarily operates in a vertical orientation, enabling gravity to assist in chip removal and providing operators with easier access to the workpiece. This design significantly enhances productivity, as it minimizes downtime associated with maintenance and setup, allowing manufacturers to produce complex geometries with high accuracy.

For beginners, understanding the components and functionality of VMC machines is crucial. These machines typically consist of a spindle, tool changer, and a worktable, which supports the material being machined. The spindle rotates tools at high speeds, allowing for various machining operations such as milling, drilling, and tapping. Additionally, with the incorporation of computer numerical control (CNC) technology, VMCs can execute intricate designs autonomously, reducing the risk of human error and improving the overall quality of produced parts. This advancement in machining technology positions VMCs as a vital asset in the competitive landscape of modern manufacturing.

Unlocking Precision: How VMC Machines Revolutionize Modern Manufacturing Techniques

| Feature | Description | Benefits |

|---|---|---|

| High Precision | VMCs offer high dimensional accuracy and repeatability, often achieving tolerances of ±0.005 mm. | Ensures that manufactured parts meet strict specifications, reducing waste and rework. |

| Versatility | Able to perform a variety of machining operations including milling, drilling, and tapping. | Streamlines manufacturing processes by reducing the need for multiple machines. |

| Automation Capability | Many VMCs support CNC programming and can operate autonomously. | Increases production efficiency and reduces labor costs. |

| User-Friendly Interface | Modern VMCs come equipped with intuitive controls and touchscreens. | Enhances operator productivity and reduces training time. |

| Material Compatibility | Can machine a wide range of materials such as metals, plastics, and composites. | Offers flexibility in manufacturing various products across industries. |

Enhancing Precision: How VMC Technology Improves Manufacturing Accuracy

In the realm of modern manufacturing, VMC (Vertical Machining Center) technology is transforming the precision landscape. Recent industry reports suggest that precision machining is experiencing a growth rate of around 7% annually, largely driven by advancements in VMC systems. These machines allow manufacturers to achieve tolerances within ±0.005 mm, a revolutionary leap from traditional machining methods. This enhanced accuracy not only minimizes waste but also significantly reduces the time required for setup and rework, which are critical factors in maintaining competitiveness.

Furthermore, the integration of AI and machine learning into VMC operations is further amplifying precision. By analyzing large datasets and optimizing machining parameters in real-time, manufacturers are seeing reductions in cycle time up to 30%. This capability enhances not only product quality but also operational efficiency. As industries continue to embrace these technologies, the synergy between VMC machinery and AI is positioned to redefine manufacturing standards, leading to unprecedented levels of accuracy and productivity.

Streamlining Production: The Role of VMC Machines in Modern Manufacturing Workflows

In the realm of modern manufacturing, VMC (Vertical Machining Center) machines play a pivotal role in streamlining production workflows. These sophisticated CNC machines enable manufacturers to perform multiple processes—such as milling, drilling, and tapping—within a single setup. This capability not only reduces the time and cost associated with transitioning between different machines but also enhances precision and minimizes the potential for errors. By consolidating tasks, VMC machines contribute to a more efficient use of resources, enabling manufacturers to meet tighter deadlines and increasing overall productivity.

Moreover, the integration of VMC machines into manufacturing workflows allows for greater flexibility and adaptability. As industries face increasingly complex designs and customized orders, the programmability of VMC machines lets manufacturers easily adjust operations without the need for extensive reconfiguration. This results in shorter lead times and the ability to quickly pivot in response to market demands. Furthermore, advancements in software and technology have made these machines increasingly user-friendly, facilitating a smoother transition for operators and enhancing the collaborative potential between man and machine in the manufacturing environment.

Choosing the Right VMC Machine: Key Factors for Optimal Performance

When selecting a Vertical Machining Center (VMC) machine, several key factors determine optimal performance for modern manufacturing. First and foremost is the machine’s size and weight capacity, which can greatly influence the range of projects it can handle. A VMC that accommodates larger workpieces can lead to increased versatility in production capabilities. Additionally, evaluating the travel distances of the axis provides insight into the machine's suitability for various types of complex machining tasks.

Moreover, the precision and accuracy of the VMC are crucial for achieving desired outcomes in manufacturing. Key specifications such as spindle speed, feed rate, and tool change time should be carefully considered, as they contribute directly to the machine's efficiency and reliability. The integration of advanced features like automatic tool changers and multi-axis capabilities can also enhance overall productivity, allowing manufacturers to optimize their processes and output. By focusing on these essential factors, businesses can ensure they choose the right VMC machine that meets their specific needs and enhances their operational performance.

Future Trends: What’s Next for VMC Technology in Modern Manufacturing?

As the manufacturing landscape evolves, VMC (Vertical Machining Center) technology is positioned at the forefront of precision engineering. Future trends indicate an increased integration of advanced automation and machine learning into VMC systems, enhancing their operational efficiency and precision. According to recent reports, the demand for high-performance materials, such as electronic-grade silicon micropowder, is projected to rise significantly, driven by industries like electronics and automotive. By 2028, the global demand for packaging fillers alone is expected to increase to 427,000 tons, highlighting the need for VMCs that can produce these advanced materials with unrivaled accuracy.

Tips: To stay ahead in the rapidly advancing manufacturing sector, companies should invest in the latest VMC technologies that not only improve output quality but also reduce waste. Embracing digital transformation through smart machine interfaces can streamline production processes, making them more adaptable to market demands.

Furthermore, the integration of intelligent chassis systems in electric vehicles signifies a push towards more complex and precise manufacturing techniques. As seen with advancements in VMC capabilities, the convergence of machinery and software is essential for maintaining competitive advantages in modern manufacturing. By leveraging these innovations, manufacturers can capitalize on emerging trends and meet the high-demand requirements of future industries.